H. Shahinian, M. Hassan, H. Cherukuri, B. Mullany

in Applied Optics Vol. 56, Issue 29, pp. 8266-8274 (2017).

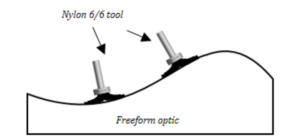

This paper details the feasibility of using fiber-based tools in a CNC environment to process optical materials, and their ability to reduce the amplitude of pre-existing mid spatial frequency (MSF) surface errors. The work is motivated by earlier research conducted by the group exploring the ability of polymeric fiber based tools to remove material from BK7 glass substrates. To evaluate these tools in a CNC environment three tasks are explored. Firstly, the ability of the tools to maintain their form and material removal profile while operating under translational conditions. Secondly, the ability of the tools to disengage and reengage with the workpiece edge and how this affects the tool’s material removal profile. Finite element (FE) modelling of the fiber-workpiece edge interaction was conducted to support the experimental work. And thirdly, to verify the deterministic behavior of the tool under full raster conditions. Testing on a 3-axis CNC machine tool demonstrated that the tooling is sufficiently robust and stable to operate under translational and rotational speeds of 30 mm/s and 1000 rpm respectively. Both the FE modeling and experimental testing confirmed the truncation of a fiber’s material removal profile as a fiber extends beyond the workpiece edge. The ability of fiber based tools to reduce MSF errors was explored both through FE modeling and experimental testing on germanium samples. Both the FE model and experimental results demonstrate that fiber based tools can successfully reduce pre-existing MSF errors.