Bin Ma, Katelynn Sharma, Kevin P. Thompson, and Jannick P. Rolland

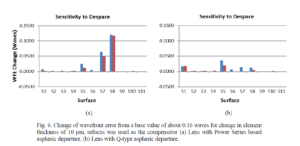

The camera lenses that are built into the current generation of mobile devices are extremely stressed by the excessively tight packaging requirements, particularly the length. As a result, the aspheric departures and slopes on the lens surfaces, when designed with conventional power series based aspheres, are well beyond those encountered in most optical systems. When the as-manufactured performance is considered, the excessive aspheric slopes result in unusually high sensitivity to tilt and decenter and even despace resulting in unusually low manufacturing yield. Qbfs polynomials, a new formulation for nonspherical optical surfaces introduced by Forbes, not only build on orthogonal polynomials, but their unique normalization provides direct access to the RMS slope of the aspheric departure during optimization. Using surface shapes with this description in optimization results in equivalent performance with reduced alignment sensitivity and higher yield. As an additional approach to increasing yield, mechanically imposed external pivot points, introduced by Bottema, can be used as a design technique to further reduce alignment sensitivity and increase yield. In this paper, the Q-type polynomials and external pivot points were applied to a mobile device camera lens designed using an active RMS slope constraint that was then compared to a design developed using conventional power series surface descriptions. Results show that slope constrained Q-type polynomial description together with external pivot points lead directly to solutions with significantly higher manufacturing yield.