N. W. Horvath, I. W. Barron, J.D. Owen, B.S. Dutterer, E. Schiesser, A. Bauer, J. P. Rolland, M. A. Davies

32nd ASPE Annual Meeting, Charlotte, NC, October 19-November 3, 2017

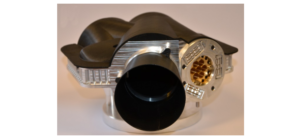

Freeform optics can allow for more compact imager designs that do not sacrifice image quality as compared to traditional designs using spherical and aspherical optics[1,2,3,4,6]. In this work, a three mirror anastigmat (TMA) off-axis in-plane optical design, as shown in Figure 1, is the baseline for a diffraction-limited, 250 mm aperture, wide-field-of-view telescope using three freeform mirrors.

The work reported here focuses on the opto-mechanical design and tolerance quantification and qualitative performance testing for this novel system design[1]. The first objective of this work was optomechanical design and the construction of the system targeting the mirror placement tolerances necessary to maintain diffraction limited performance. The second objective of this work was to connect measurements of the attained assembly uncertainty to image quality. The end goal is to systematically connect measured assembly uncertainties with image performance and to provide feedback to optical designers on the methods for and the costs of maintaining these tolerances. Although the study here targeted a 1/3rd scale system with an 83 mm aperture, the methods are applicable to larger scale systems as well. Methods of precision manufacturing[5], precision assembly using kinematic mounts[7,8], and precision metrology are combined to achieve this goal.