Richard Leach, Christopher Evans, Liangyu He, Angela Davies, Angela Duparré, Andrew Henning, Christopher W Jones and Daniel O’Connor

Published 22 January 2015 • © 2015 IOP Publishing Ltd • , ,

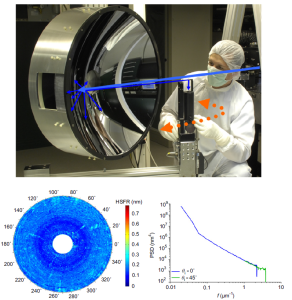

Control of surface topography has always been of vital importance for manufacturing and many other engineering and scientific disciplines. However, despite over one hundred years of quantitative surface topography measurement, there are still many open questions. At the top of the list of questions is ‘Are we getting the right answer?’ This begs the obvious question ‘How would we know?’ There are many other questions relating to applications, the appropriateness of a technique for a given scenario, or the relationship between a particular analysis and the function of the surface. In this first ‘open questions’ article we have gathered together some experts in surface topography measurement and asked them to address timely, unresolved questions about the subject. We hope that their responses will go some way to answer these questions, address areas where further research is required, and look at the future of the subject. The first section ‘Spatial content characterization for precision surfaces’ addresses the need to characterise the spatial content of precision surfaces. Whilst we have been manufacturing optics for centuries, there still isn’t a consensus on how to specify the surface for manufacture. The most common three methods for spatial characterisation are reviewed and compared, and the need for further work on quantifying measurement uncertainties is highlighted. The article is focussed on optical surfaces, but the ideas are more pervasive. Different communities refer to ‘figure, mid-spatial frequencies, and finish’ and ‘form, waviness, and roughness’, but the mathematics are identical. The second section ‘Light scattering methods’ is focussed on light scattering techniques; an important topic with in-line metrology becoming essential in many manufacturing scenarios. The potential of scattering methods has long been recognized; in the ‘smooth surface limit’ functionally significant relationships can be derived from first principles for statistically stationary, random surfaces. For rougher surfaces, correlations can be found experimentally for specific manufacturing processes. Improvements in computational methods encourage us to revisit light scattering as a powerful and versatile tool to investigate surface and thin film topographies, potentially providing information on both topography and defects over large areas at high speed. Future scattering techniques will be applied for complex film systems and for sub-surface damage measurement, but more research is required to quantify and standardise such measurements. A fundamental limitation of all topography measurement systems is their finite spatial bandwidth, which limits the slopes that they can detect. The third section ‘Optical measurements of surfaces containing high slope angles’ discusses this limitation and potential methods to overcome it. In some cases, a rough surface can allow measurement of slopes outside the classical optics limit, but more research is needed to fully understand this process. The last section ‘What are the challenges for high dynamic range surface measurement?’ presents the challenge facing metrologists by the use of surfaces that need measurement systems with very high spatial and temporal bandwidths, for example, those found in roll-to-roll manufacturing. High resolution, large areas and fast measurement times are needed, and these needs are unlikely to be fulfilled by developing a single all-purpose instrument. A toolbox of techniques needs to be developed which can be applied for any specific manufacturing scenario. The functional significance of surface topography has been known for centuries. Mirrors are smooth. Sliding behaviour depends on roughness. We have been measuring surfaces for centuries, but we still face many challenges. New manufacturing paradigms suggest that we need to make rapid measurements online that relate to the functional performance of the surface. This first ‘open questions’ collection addresses a subset of the challenges facing the surface metrology community. There are many more challenges which we would like to address in future ‘open questions’ articles. We welcome your feedback and your suggestions.

Control of surface topography has always been of vital importance for manufacturing and many other engineering and scientific disciplines. However, despite over one hundred years of quantitative surface topography measurement, there are still many open questions. At the top of the list of questions is ‘Are we getting the right answer?’ This begs the obvious question ‘How would we know?’ There are many other questions relating to applications, the appropriateness of a technique for a given scenario, or the relationship between a particular analysis and the function of the surface. In this first ‘open questions’ article we have gathered together some experts in surface topography measurement and asked them to address timely, unresolved questions about the subject. We hope that their responses will go some way to answer these questions, address areas where further research is required, and look at the future of the subject. The first section ‘Spatial content characterization for precision surfaces’ addresses the need to characterise the spatial content of precision surfaces. Whilst we have been manufacturing optics for centuries, there still isn’t a consensus on how to specify the surface for manufacture. The most common three methods for spatial characterisation are reviewed and compared, and the need for further work on quantifying measurement uncertainties is highlighted. The article is focussed on optical surfaces, but the ideas are more pervasive. Different communities refer to ‘figure, mid-spatial frequencies, and finish’ and ‘form, waviness, and roughness’, but the mathematics are identical. The second section ‘Light scattering methods’ is focussed on light scattering techniques; an important topic with in-line metrology becoming essential in many manufacturing scenarios. The potential of scattering methods has long been recognized; in the ‘smooth surface limit’ functionally significant relationships can be derived from first principles for statistically stationary, random surfaces. For rougher surfaces, correlations can be found experimentally for specific manufacturing processes. Improvements in computational methods encourage us to revisit light scattering as a powerful and versatile tool to investigate surface and thin film topographies, potentially providing information on both topography and defects over large areas at high speed. Future scattering techniques will be applied for complex film systems and for sub-surface damage measurement, but more research is required to quantify and standardise such measurements. A fundamental limitation of all topography measurement systems is their finite spatial bandwidth, which limits the slopes that they can detect. The third section ‘Optical measurements of surfaces containing high slope angles’ discusses this limitation and potential methods to overcome it. In some cases, a rough surface can allow measurement of slopes outside the classical optics limit, but more research is needed to fully understand this process. The last section ‘What are the challenges for high dynamic range surface measurement?’ presents the challenge facing metrologists by the use of surfaces that need measurement systems with very high spatial and temporal bandwidths, for example, those found in roll-to-roll manufacturing. High resolution, large areas and fast measurement times are needed, and these needs are unlikely to be fulfilled by developing a single all-purpose instrument. A toolbox of techniques needs to be developed which can be applied for any specific manufacturing scenario. The functional significance of surface topography has been known for centuries. Mirrors are smooth. Sliding behaviour depends on roughness. We have been measuring surfaces for centuries, but we still face many challenges. New manufacturing paradigms suggest that we need to make rapid measurements online that relate to the functional performance of the surface. This first ‘open questions’ collection addresses a subset of the challenges facing the surface metrology community. There are many more challenges which we would like to address in future ‘open questions’ articles. We welcome your feedback and your suggestions.