PhD student Sivan Salzman, Prof. John Lambropoulos and Prof. Stephen Jacobs recently published a paper, “Magnetorheologicalfinishing with chemically-modified fluids for studying material removal of single crystal ZnS” in the Proceedings of SPIE Optifab 2013

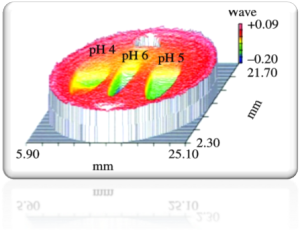

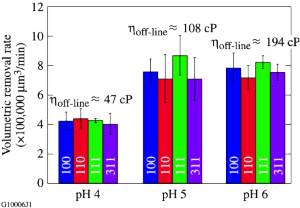

Abstract: Magnetorheologicalfinishing (MRF) of polycrystalline (pc), chemical-vapor–deposited (CVD) zinc sulfide (ZnS) can leave millimeter-size artifacts on the part surface. These pebble-like features come from the anisotropic mechanical and chemical properties of the ceramic material and from the CVD growth process itself. The resulting surface texture limits the use of MRF for precision polishing of aspheric and freeform shapes using this important infrared (IR) ceramic. In this work, mechanical (microhardness testing) and chemical (acid etching) studies are performed on the four

single-crystal orientations found at the surface of pc ZnS: 100, 110, 111, and 311. The (111) plane is 35% to 55% harder and 30% to 40% more resistant to chemical etching than the other three planes. This high degree of variation in these properties helps to explain the surface texture developed from MRF of the polycrystalline material. Surface characterization of these single-crystal orientations of ZnS for material removal and roughness with chemically modified MR fluids at various pH levels between pH 4 and pH 6 are presented for the first time. These results will guide the development of new acid MR fluids for polishing pc CVD ZnS.

Spring 2014